About LEA®

Highly efficient air disinfection; can be used anywhere – with almost limitless possibilities for application

The LEA® Concept

LEA® makes it simple and cost-efficient to enhance the performance air disinfection systems and air purifiers. Conventional pathogen-reduction technologies can be replaced or upgraded using LEA®, with its unique combination of highly efficient disinfection rates and reliable operation. LEA® will safely boost the performance of your existing appliance to a completely new level with zero emissions of ozone and NOx.

Key Facts

Effective in a wide range of applications

Wirksam gegen Viren, Bakterien und Schimmelsporen

Highly efficient

An inactivation rate of up to 99.99992%

No emissions that are damaging to health

Continuous operation with no emissions of ozone or NOx

Flexible application

Can be integrated in all kinds of different system architectures.

Extremely quiet.

Continuous operation at less than 35dBA

Environmentally friendly

Chemical-free and no waste-buildup

Can be fitted anywhere

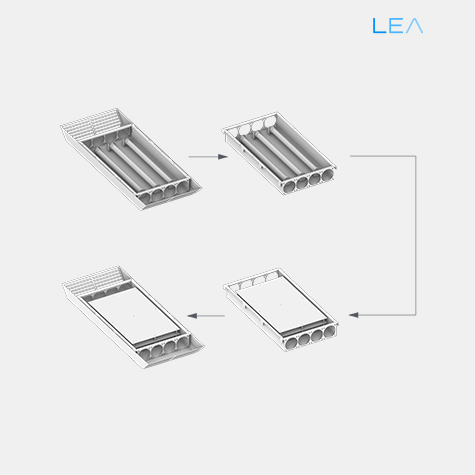

The homogeneous buildup of the LEA® microelectrode matrix ensures that it can be laid out to fit any geometry. . It can be integrated into any system architecture through the installation of individually shaped panels equipped with microelectrodes. These bespoke panels may be either flat or curved to match the shape of the underlying structure. This flexibility ensures that LEA® can be integrated fully into any architecture no matter what its shape or dimensions.

Background

LEA® was developed during the Covid-19 pandemic, at a time when air disinfection was seen as of vital importance. The concept for an innovative technology designed to reduce the risk of infection in medical installations was presented to the European Commission. A contract for development was issued shortly thereafter.

A scientific basis for the technology was developed in collaboration with an international team of doctors and microbiologists as part of the EU Horizon2020 “CleanAir” project. This enabled further steps such as the construction of prototypes and the implementation of laboratory tests and medical field tests.

The test results were very promising. It quickly became clear that LEA® has the potential to set new standards for air disinfection technology efficiency. An international patent has therefore been registered.

We now want to offer other OEMs the opportunity to incorporate the benefits of LEA® technology into their own products and solutions.

Our company

Villinger Research & Development GmbH traces its roots back to the early 1980s, when Markus Villinger began developing new concepts for the aerospace industry. . Some of the technologies he patented are still considered “state-of-the-art” today. This spirit of innovation has stayed with us over the years. Villinger GmbH has established itself as an international research and development organization, that is active in various industries.

Today our company is still dedicated to the advanced lab-to-fab development of technologies that set new standards in their fields. In the meantime, we can look back on a string of innovations that have established themselves in the market. Working in close cooperation with renowned scientific partners, we form the interface between conceptual research and development, followed by the commercial rollout of our products on the market.